Kumarobhothi ezimboni, izinto zokuphatha kungenye yezinhlelo ezibaluleke kakhulu ekusebenzeni kwawo kokubamba.Njengohlobo lwemishini yokusebenza enokwehlukahlukana okuqinile, ukuphothulwa ngempumelelo komsebenzi wokusebenza kwerobhothi lezimboni kuncike ngqo kumshini wokubopha.Ngakho-ke, indlela yokubopha ekugcineni kwerobhothi kufanele yakhelwe ngokwemisebenzi yangempela yokusebenza kanye nezidingo zendawo yokusebenza.Lokhu kuholela ekuhlukeni kwezinhlobo zesakhiwo se-clamping mechanism.

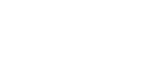

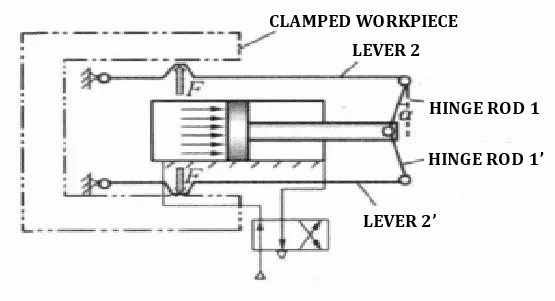

Umfanekiso 1 Ubudlelwane phakathi kwezakhi, izici kanye nemingcele yesiphetho sokugcina Izindlela eziningi zokubopha zemishini ziwuhlobo lwezinzipho ezineminwe emibili, ezingahlukaniswa zibe: uhlobo olujikelezayo kanye nohlobo lokuhumusha ngokuya ngendlela yokunyakaza kweminwe;izindlela ezihlukene zokubopha zingahlukaniswa zibe ukwesekwa kwangaphakathi Ngokwezici zesakhiwo, zingahlukaniswa zibe uhlobo lwe-pneumatic, uhlobo lukagesi, uhlobo lwe-hydraulic kanye nendlela yabo yokuhlanganisa ehlanganisiwe.

I-pneumatic end clamping mechanism

Umthombo womoya wokudluliswa kwe-pneumatic kulula kakhulu ukutholakala, isivinini sesenzo siyashesha, indawo yokusebenza ayinakho ukungcola, futhi i-fluidity ingcono kunesistimu ye-hydraulic, ukulahlekelwa kwengcindezi kuncane, futhi ifanele isikhathi eside- ukulawulwa kwebanga.Okulandelayo kukhona ama-manipulators we-pneumatic amaningana:

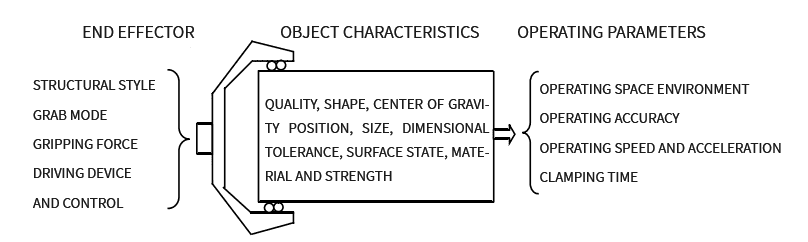

1. I-Rotary link lever-type clamping mechanism Iminwe yale divayisi (njengeminwe emise okwe-V, iminwe egobile) igxiliswe kumshini wokugoqa ngamabhawudi, okulula ukushintshwa ngawo, ukuze ikhulise kakhulu ukusetshenziswa kwe-clamping. i-clamping mechanism.

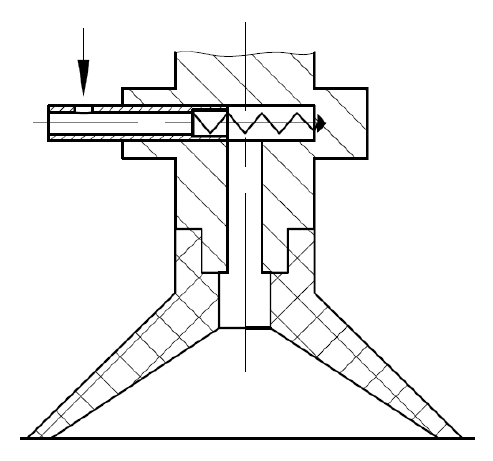

Umfanekiso 2 Isakhiwo sendlela yokuhlanganisa yeleva yesixhumanisi esizungezayo 2. Uhlobo lwenduku eqondile yokuhumusha isilinda esiphindwe kabili Indlela yokubopha Ingxenye yomunwe yale ndlela yokubopha ngokuvamile ifakwa entongeni eqondile efakwe isihlalo somunwe ekugcineni.Lapho kusetshenziswa izimbotshana zezinduku ezimbili zesilinda esibamba kabili, iphiston kancane kancane lizohamba liye phakathi kuze kube yilapho ucezu lokusebenza luboshiwe.

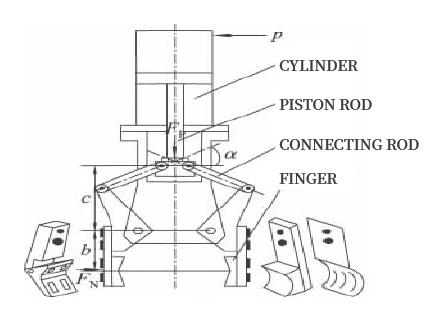

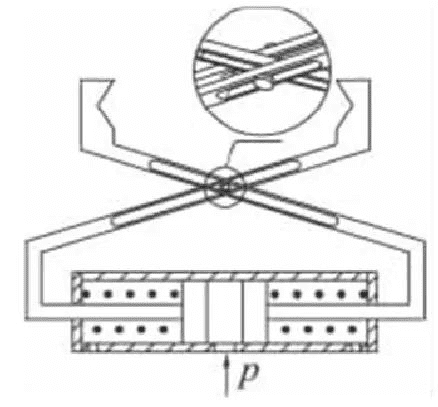

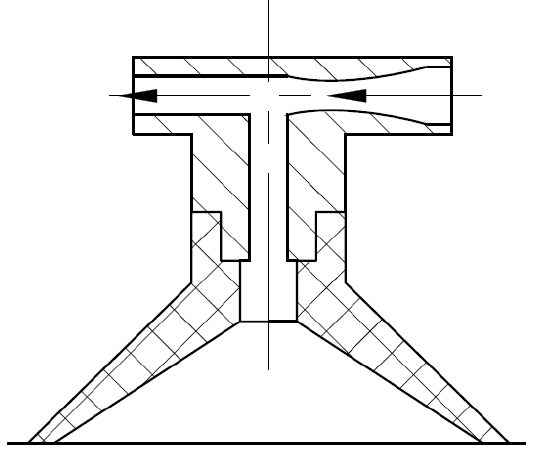

Umfanekiso 3 Umdwebo wesakhiwo wendlela yokubamba yokuhumusha eyi-straight-cylinder double-cylinder 3. Induku yokuxhuma yohlobo lwe-cross-cylinder clamping mechanism ngokuvamile yakhiwa isilinda esiphindwe kabili esibambayo kanye nomunwe wohlobo oluphambene.Ngemva kokuba igesi ingena emgodini ophakathi we-cylinder, izocindezela ama-pistons amabili ukuba ahambe ezinhlangothini zombili, ngaleyo ndlela iqhube induku yokuxhuma ukuze ihambe, futhi iziphetho zeminwe eziphambanayo zizolungisa ngokuqinile ucezu lokusebenza;uma kungekho moya ongena emgodini ophakathi, i-piston izoba ngaphansi kwesenzo se-spring thrust Setha kabusha, i-workpiece engaguquki izokhishwa.

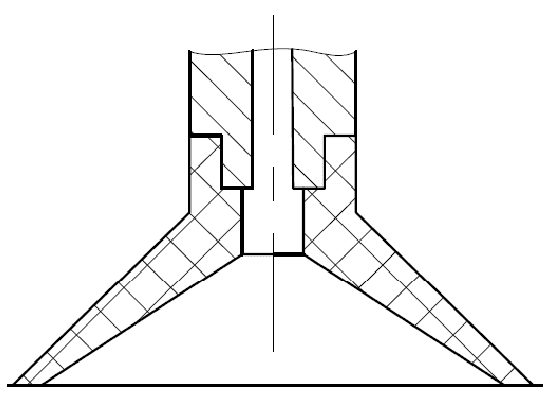

Umfanekiso 4. Isakhiwo sendlela yokubopha yokuhumusha eyi-cross-cylinder double Izingcezu zokusebenza ezinezindonga ezincane ezinezimbobo zangaphakathi.Ngemuva kokuthi i-clamping mechanism ibambe i-workpiece, ukuze kuqinisekiswe ukuthi ingabekwa kahle ngembobo yangaphakathi, ngokuvamile iminwe emi-3 ifakiwe.

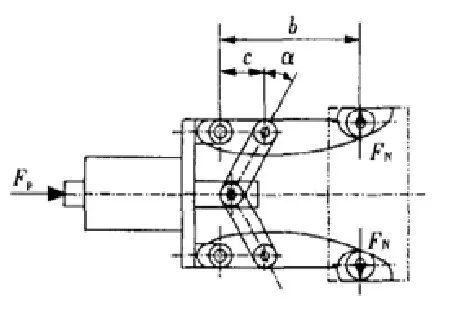

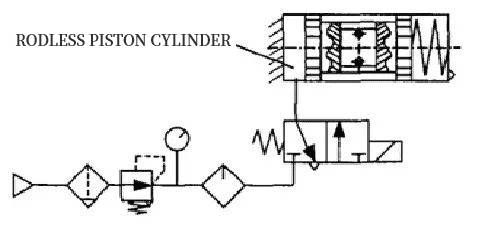

Umfanekiso 5 Umdwebo wesakhiwo wendlela yokubamba yohlobo lwe-lever yenduku yosekelo yangaphakathi 5. I-booster mechanism eshayelwa isilinda yepiston engagxili ye-rodless Ngaphansi kwesenzo samandla asentwasahlobo, ukuhlehla kubonakala ngevalvu ye-solenoid enezindawo ezimbili.

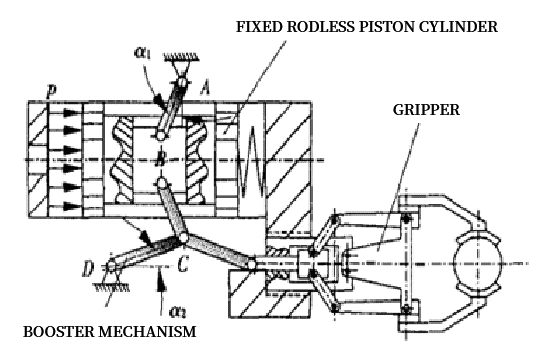

Umfanekiso 6 Uhlelo lwe-pneumatic yesilinda ye-piston engaguquki Isilayidi soguquko sifakwe endaweni ye-radial yepiston yesilinda se-rodless piston, futhi izinti ezimbili zamahinge zincike ngokulinganayo emikhawulweni yomibili yesilayidi.Uma amandla angaphandle esebenza ku-piston, i-piston izonyakaza kwesokunxele nakwesokudla, ngaleyo ndlela iphushe isilayidi ukuthi siye phezulu naphansi.Lapho uhlelo luboshiwe, iphoyinti lehinge B lizokwenza ukunyakaza okuyisiyingi kuzungeza iphuzu A, futhi ukunyakaza okuya phezulu naphansi kwesilayidi kungangeza izinga lenkululeko, futhi ukuzungeza kwephuzu C kungena esikhundleni sokuzulazula kwayo yonke isilinda. vimba.

Umfanekiso 7 Indlela yokuthuthukisa amandla eshayelwa isilinda sepiston engagxili

Lapho i-valve yokulawula eqondisayo yomoya ocindezelwe isesimweni sokusebenza kwesokunxele njengoba kukhonjisiwe emfanekisweni, umgodi wesokunxele we-cylinder ye-pneumatic, okungukuthi, i-rodless cavity, ungena emoyeni ocindezelwe, futhi i-piston izothuthela kwesokudla ngaphansi. isenzo somfutho womoya, ukuze i-angle yokucindezela α yehinge rod iyancipha kancane kancane.Okuncane, umfutho womoya ukhuliswa umthelela we-engeli, bese amandla adluliselwa ku-lever ye-boosting force lever mechanism, amandla azophinde akhuliswe, futhi abe amandla F ekubambeni ucezu lokusebenza.Lapho i-valve yokulawula eqondisayo isesimweni sokusebenza sendawo efanele, imbobo yenduku engxenyeni engakwesokudla yesilinda somoya ingena emoyeni ocindezelweyo, iphushe i-piston ukuze iye kwesokunxele, bese umshini wokubopha ukhulula ucezu lokusebenza.

Umfanekiso 8. I-clamping pneumatic manipulator yangaphakathi yehinge rod kanye ne-2 lever series booster mechanism

Indlela yokuqinisa i-Air suction end emibili

I-air suction end clamping mechanism isebenzisa amandla okumunca akhiwe ukucindezela okungekuhle enkomishini yokumunca ukuhambisa into.Isetshenziswa kakhulu ukubamba ingilazi, iphepha, insimbi nezinye izinto ezinomumo omkhulu, ukushuba okumaphakathi kanye nokungaqini kahle.Ngokwezindlela zokukhiqiza umfutho ongemuhle, ingahlukaniswa ngezinhlobo ezilandelayo: 1. Inkomishi yokumunca yokukhama Umoya osenkomishini yokumunca ukhishwa ngamandla okucindezela ashona phansi, ukuze umfutho ongemuhle ukhiqizwe ngaphakathi kwenkomishi yokumunca, kanye nokudonsa. amandla akheka ukumunca into.Isetshenziselwa ukubamba ama-workpieces anesimo esincane, ubukhulu obuncane kanye nesisindo esincane.

Umfanekiso 9 Umdwebo wesakhiwo wenkomishi yokumunca 2. Ivalvu yokulawula inkomishi yokudonsa komoya egelezayo ifafaza umoya ocindezelwe ophuma empompini yomoya ophuma emlonyeni, futhi ukugeleza komoya ocindezelwe kuzokhiqiza ijethi enesivinini esikhulu, okuzothatha kude nomoya enkomishini yokumunca, ukuze inkomishi yokumunca ibe senkomishini yokumunca.Umfutho ongemuhle ukhiqizwa ngaphakathi, futhi ukumunca okwakhiwa ukucindezela okungekuhle kungamunca isiqeshana somsebenzi.

Umfanekiso 10 Umdwebo wesakhiwo wokugeleza komoya inkomishi yokumunca ingcindezi

3. Inkomishi yokumunca iphampu yevacuum isebenzisa ivalvu yokulawula uzibuthe kagesi ukuxhuma iphampu yevacuum nenkomishi yokumunca.Lapho umoya uphonswa, umoya osemgodini wenkomishi yokumunca uyakhishwa, wenze umfutho ongemuhle futhi umunce into.Ngokuphambene, lapho i-valve yokulawula ixhuma inkomishi yokumunca nomoya, inkomishi yokumunca ilahlekelwa ukumunca futhi ikhiphe ucezu lokusebenza.

Umfanekiso 11 Umdwebo wesakhiwo wenkomishi yokumunca iphampu yevacuum

I-hydraulic end clamping mechanism

1. Indlela yokubopha evamise ukuvaleka: Ithuluzi lokumba liqiniswa ngamandla aqinile angaphambi kokuqinisa entwasahlobo futhi likhishwe ngamanzi.Uma i-clamping mechanism ingawenzi umsebenzi wokubamba, isesimweni sokubopha ithuluzi lokubhoboza.Isakhiwo sawo esiyisisekelo siwukuthi iqembu leziphethu ezicindezelwe ngaphambili lisebenza ngendlela yokwandisa amandla njengerempu noma i-lever, ukuze isihlalo sokushelela sinyakaze nge-axially, sishayele isiliphu ukuba sinyakaze nge-radially, futhi ibambe ithuluzi lokubhola;amafutha anengcindezi ephezulu angena esihlalweni sokushibilika futhi I-hydraulic cylinder eyakhiwe yi-casing iqhubeka icindezela isiphethu, okwenza isihlalo sokushelela kanye nesiliphu sihambe ngokuphambene, sikhulule ithuluzi lokubhoboza.2. Indlela yokubopha evamise ukuvuleka: Ivamise ukusebenzisa ukukhululwa kwentwasahlobo kanye ne-hydraulic clamping, futhi iba sesimweni sokukhululwa lapho umsebenzi wokubamba ungenziwa.I-clamping mechanism incike ekugxilweni kwe-hydraulic cylinder ukukhiqiza amandla okubamba, futhi ukuncipha komfutho kawoyela kuzoholela ekwehlisweni kwamandla okubamba.Ngokuvamile, ukukhiya kwe-hydraulic nokusebenza okuthembekile kufakwa kumjikelezo kawoyela ukuze kugcinwe umfutho kawoyela.3. I-hydraulic tightening clamping mechanism: Kokubili ukuxegisa nokubopha kubonakala ngomfutho we-hydraulic.Uma ama-inlets kawoyela amasilinda e-hydraulic ezinhlangothini zombili exhunywe kuwoyela onengcindezi ephezulu, ama-slip azovala phakathi nendawo ngokunyakaza kwepiston, abambe ithuluzi lokumba, futhi aguqule i-The high pressure oil inlet, ama-slip akhona. kude nendawo, futhi ithuluzi lokubhoboza liyakhululwa.

4. I-Compound hydraulic clamping mechanism: Lo mshini une-hydraulic cylinder eyinhloko kanye ne-auxiliary hydraulic cylinder, futhi isethi yemithombo ye-disc ixhunywe ohlangothini lwe-hydraulic cylinder.Lapho uwoyela onengcindezi ephezulu ungena kusilinda esiwuketshezi olunamandla, uphusha isivikelo se-hydraulic cylinder block ukuze sinyakaze, bese edlula kukholamu ephezulu.Amandla adluliselwa esihlalweni sokushelela eceleni kwesilinda se-hydraulic cylinder, i-disc spring iphinde icindezeleke, futhi isihlalo sokushelela siyahamba;ngesikhathi esifanayo, isihlalo sokushelela ohlangothini oluyinhloko lwe-hydraulic cylinder sihamba ngaphansi kwesenzo samandla asentwasahlobo, sikhulula ithuluzi lokubhoboza.

Izinto ezine zokubopha ekupheleni kazibuthe

Ihlukaniswe yaba izinkomishi zokumunca zikagesi nezinkomishi zokudonsa unomphela.

I-electromagnetic chuck iwukuheha futhi ikhulule izinto ze-ferromagnetic ngokuvula nokuvala amandla akhona kukhoyili, ikhiqize futhi iqede amandla kazibuthe.Inkomishi yokumunca kazibuthe ehlala njalo isebenzisa amandla kazibuthe ensimbi kazibuthe ehlala njalo ukuheha izinto ze-ferromagnetic.Ishintsha umjikelezo womugqa wenkundla kazibuthe enkomishini yokumunca ngokuhambisa into ehlukanisa uzibuthe, ukuze kufezwe injongo yokuheha nokukhulula izinto.Kodwa futhi iwumunyisi, futhi amandla okumunca we-sucker unomphela awamkhulu njengalawo we-sucker kagesi.

Isikhathi sokuthumela: May-31-2022