Kunezindlela ezintathu zokulawula ze-servo motor: ishayela, i-analog nokuxhumana.Kufanele siyikhethe kanjani imodi yokulawula ye-servo motor ezimeni ezahlukahlukene zohlelo?

1. Imodi yokulawula i-Pulse ye-servo motor

Kweminye imishini emincane emi yodwa, ukusetshenziswa kokulawula ukushaya kwenhliziyo ukubona ukuma kwemoto kufanele kube indlela esetshenziswa kakhulu.Le ndlela yokulawula ilula futhi kulula ukuyiqonda.

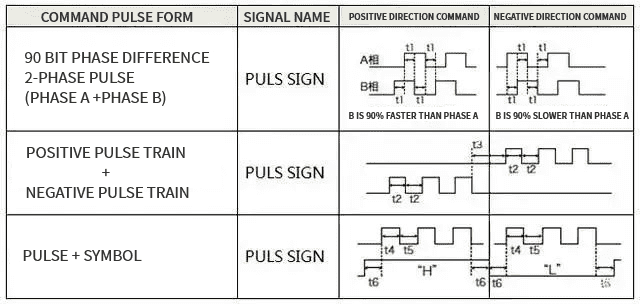

Umbono oyisisekelo wokulawula: inani eliphelele lama-pulses linquma ukuhamba kwemoto, futhi imvamisa yokushaya inquma isivinini semoto.I-pulse ikhethiwe ukuze ibone ukulawula kwe-servo motor, vula imanuwali ye-servo motor, futhi ngokuvamile kuzoba netafula elifana nalokhu okulandelayo:

Zombili ziwukulawula ukushaya kwenhliziyo, kodwa ukuqaliswa kuhlukile:

Okokuqala ukuthi umshayeli uthola ama-pulse anesivinini esikhulu (A no-B) amabili, bese enquma indlela yokuzungezisa yemoto ngomehluko wesigaba phakathi kwama-pulses amabili.Njengoba kuboniswe esithombeni esingenhla, uma isigaba B singama-degree angu-90 ngokushesha kunesigaba A, siwukuzungezisa phambili;bese kuthi isigaba B sihamba kancane ngo-90 degrees kunesigaba A, siwukuzungezisa okuhlanekezelwe.

Ngesikhathi sokusebenza, ama-pulses ezigaba ezimbili zalokhu kulawula ayashintshana, ngakho-ke sibiza futhi le ndlela yokulawula umehluko wokulawula.Inezici zokuhlukanisa, okubonisa futhi ukuthi le ndlela yokulawula, i-pulse yokulawula inekhono eliphakeme lokulwa nokuphazamiseka, kwezinye izimo zohlelo lokusebenza ngokuphazamiseka okunamandla, le ndlela iyakhethwa.Kodwa-ke, ngale ndlela, i-motor shaft eyodwa idinga ukuthatha amachweba amabili we-high-speed pulse, angasifanele isimo lapho amachweba we-pulse speed aqinile.

Okwesibili, umshayeli usathola ama-pulse amabili anesivinini esiphezulu, kodwa ama-pulse amabili anesivinini esikhulu awekho ngesikhathi esisodwa.Uma ukushaya kwenhliziyo okukodwa kukusimo sokuphumayo, okunye kufanele kube sesimweni esingavumelekile.Uma le ndlela yokulawula ikhethiwe, kufanele kuqinisekiswe ukuthi kunokukhishwa kwe-pulse okukodwa ngesikhathi esisodwa.Ama-pulses amabili, okukhiphayo okukodwa kugijima ngendlela eqondile kanti enye igijima ngendlela engalungile.Njengakulesi simo esingenhla, le ndlela idinga futhi izimbobo ezimbili ze-high-speed pulse ze-motor shaft eyodwa.

Uhlobo lwesithathu ukuthi isignali ye-pulse eyodwa kuphela edinga ukunikezwa kumshayeli, futhi ukusebenza phambili nokuhlehla kwemoto kunqunywa isignali eyodwa ye-IO.Le ndlela yokulawula kulula ukuyilawula, futhi ukusebenza kwensiza yembobo ye-high-speed pulse nakho kukuncane kakhulu.Ngokujwayelekile amasistimu amancane, le ndlela ingakhethwa.

Okwesibili, indlela yokulawula i-analog ye-servo motor

Esimweni sohlelo lokusebenza esidinga ukusebenzisa i-servo motor ukuze siqaphele ukulawula isivinini, singakhetha inani le-analog ukuze sibone ukulawulwa kwesivinini semoto, futhi inani lenani le-analog linquma isivinini sokugijima semoto.

Kunezindlela ezimbili zokukhetha inani le-analog, lamanje noma i-voltage.

Imodi ye-Voltage: Udinga kuphela ukwengeza i-voltage ethile kutheminali yesiginali yokulawula.Kwezinye izimo, ungasebenzisa i-potentiometer ukuze uzuze ukulawula, okulula kakhulu.Noma kunjalo, i-voltage ikhethwa njengesignali yokulawula.Endaweni eyinkimbinkimbi, i-voltage iphazamiseka kalula, okuholela ekulawuleni okungazinzile.

Imodi yamanje: Imojula ehambisanayo yokuphumayo iyadingeka, kodwa isignali yamanje inamandla aqinile okumelana nokuphazamiseka futhi ingasetshenziswa ezimeni eziyinkimbinkimbi.

3. Imodi yokulawula ukuxhumana kwe-servo motor

Izindlela ezijwayelekile zokubona ukulawula kwe-servo motor ngokuxhumana i-CAN, i-EtherCAT, i-Modbus, ne-Profibus.Ukusebenzisa indlela yokuxhumana ukulawula injini kuyindlela yokulawula ekhethwayo kwezinye izimo eziyinkimbinkimbi nezinkulu zohlelo lokusebenza.Ngale ndlela, ubukhulu besistimu kanye nenani lama-motor shafts kungenziwa kalula ngaphandle kwezintambo zokulawula eziyinkimbinkimbi.Isistimu eyakhiwe iguquguquka kakhulu.

Okwesine, ingxenye yokwandisa

1. I-Servo motor torque control

Indlela yokulawula i-torque ukusetha i-torque yangaphandle ye-motor shaft ngokusebenzisa okokufaka kwenani le-analog yangaphandle noma isabelo sekheli eliqondile.Ukusebenza okuqondile ukuthi, isibonelo, uma i-10V ihambisana ne-5Nm, lapho ubuningi be-analog yangaphandle isethelwe ku-5V, i-motor shaft ithi Okuphumayo kungu-2.5Nm.Uma umthamo we-motor shaft ungaphansi kuka-2.5Nm, injini isesimweni sokusheshisa;lapho umthwalo wangaphandle ulingana no-2.5Nm, i-motor isesimweni esingaguquki noma sokumisa;lapho umthwalo wangaphandle ungaphezu kuka-2.5Nm, injini isesimweni sokuhlehla noma sokuhlehla ukusheshisa.I-torque emisiwe ingashintshwa ngokushintsha ukulungiselelwa kobuningi be-analog ngesikhathi sangempela, noma inani lekheli elihambisanayo lingashintshwa ngokuxhumana.

Isetshenziswa kakhulu kumadivayisi asongayo kanye nawokuqaqa anezidingo eziqinile kumandla wento, njengamadivaysi asongayo noma okokusebenza okudonsa i-fiber optical.Ukulungiselelwa kwe-torque kufanele kushintshwe noma kunini ngokuya ngokushintsha kwerediyasi emazombezombe ukuze kuqinisekiswe ukuthi amandla ento angeke ashintshe ngokushintsha kwerediyasi emazombezombe.izinguquko nge-radius emazombezombe.

2. Servo motor isikhundla control

Kumodi yokulawula indawo, isivinini sokuzungezisa ngokuvamile sinqunywa imvamisa yama-pulses okokufaka ngaphandle, futhi i-engeli yokuzungeza inqunywa inani lama-pulses.Amanye ama-servos angabela ngokuqondile isivinini nokufuduka ngokuxhumana.Njengoba imodi yesikhundla ingaba nokulawula okuqinile kwejubane nendawo, ngokuvamile isetshenziswa kumishini yokubeka, amathuluzi omshini we-CNC, imishini yokunyathelisa nokunye.

3. Imodi yesivinini se-Servo motor

Isivinini sokuzungezisa singalawulwa ngokokufaka kwenani le-analog noma imvamisa yokushaya kwenhliziyo.Imodi yesivinini ingase isetshenziselwe ukubeka lapho isilawuli se-PID esiyiluphu sangaphandle sedivayisi yokulawula ephezulu sinikezwa, kodwa isignali yendawo yemoto noma isignali yendawo yomthwalo oqondile kufanele ithunyelwe kukhompyutha ephezulu.Impendulo yokusetshenziswa kokusebenza.Imodi yokuma futhi isekela iluphu yangaphandle yokulayisha okuqondile ukuze kutholwe isignali yendawo.Ngalesi sikhathi, isifaki khodi ekugcineni kwe-motor shaft sithola kuphela isivinini semoto, futhi isignali yendawo inikezwa idivayisi yokugcina eqondile yokugcina umthwalo.Inzuzo yalokhu ukuthi inganciphisa inqubo yokudlulisela okuphakathi.Iphutha likhulisa ukunemba kokuma kwesistimu yonke.

4. Khuluma ngezindandatho ezintathu

I-servo ngokuvamile ilawulwa izihibe ezintathu.Okubizwa ngokuthi ama-loops amathathu amasistimu wokulungisa we-PID avaliwe avaliwe.

Ilophu ye-PID engaphakathi impela iyiluphu yamanje, eyenziwa ngokuphelele ngaphakathi komshayeli we-servo.Umphumela wamanje wesigaba ngasinye semoto kumotho utholwa idivayisi yeHholo, futhi impendulo engeyinhle isetshenziselwa ukulungisa ukulungiselelwa kwamanje kokulungiswa kwe-PID, ukuze kuzuzwe ukuphuma kwamanje kuseduze ngangokunokwenzeka.Ngokulingana nesethi yamanje, i-loop yamanje ilawula i-torque ye-motor, ngakho-ke kumodi ye-torque, umshayeli unomsebenzi omncane kakhulu kanye nempendulo esheshayo esheshayo.

Iluphu yesibili yiluphu yesivinini.Ukulungiswa kwe-PID yempendulo engemihle kwenziwa ngesignali etholiwe yesishumeki semoto.I-PID ephumayo ku-loop yayo iyisilungiselelo esiqondile se-loop yamanje, ngakho ukulawulwa kwe-loop yesivinini kuhlanganisa iluphu yesivinini kanye neluphu yamanje.Ngamanye amazwi, noma iyiphi imodi kumele isebenzise iluphu yamanje.Iluphu yamanje iyisisekelo sokulawula.Ngenkathi isivinini nesimo kulawulwa, isistimu empeleni ilawula yamanje (torque) ukuze kuzuzwe ukulawulwa okuhambisanayo kwejubane nendawo.

Iluphu yesithathu yiluphu yendawo, okuyiluphu engaphandle.Ingakhiwa phakathi komshayeli nesishumeki semoto noma phakathi kwesilawuli sangaphandle nesishumeki semoto noma umthwalo wokugcina, kuye ngesimo sangempela.Njengoba okukhiphayo kwangaphakathi kweluphu yokulawula indawo kuwukusetha iluphu yesivinini, kumodi yokulawula indawo, isistimu yenza imisebenzi yawo wonke amalophu amathathu.Ngalesi sikhathi, isistimu inenani elikhulu lokubala kanye nesivinini sokuphendula esinensayo esiguqukayo.

Ngenhla kuvela e-Chengzhou News

Isikhathi sokuthumela: May-31-2022